Environmental, Social and Governance

About Us

BioFashionTech is a startup which prides itself on sustainability. As the fashion industry is one of the most polluting in the world, startups and companies such as BioFashionTech have a key role to play in ensuring the industry does not continue on this path. Our ESG (environmental, social and governance) page quantifiably details how we contribute towards sustainability goals and ultimately to a truly circular fashion economy. Read more on this page to see how we are working towards these goals.

Turning Waste into Value: A New Approach to End-of-Life Textiles

At BioFashionTech, sustainability isn’t just a feature, it’s the foundation. Since the inception of BioFashionTech, we have been on a mission to revolutionise the textile industry. Every fiber we touch tells a story of transformation, where textile waste once destined for incineration or landfill is given new life through our cutting-edge biotechnological process. Our patent-pending enzymatic recycling process will change the way we think of textile waste from a laborious task requiring sorting, mechanical breaking down, and/or harsh chemicals to an environmentally friendly alternative which is low-cost, not energy intensive and actively contributes towards a truly circular fashion economy.

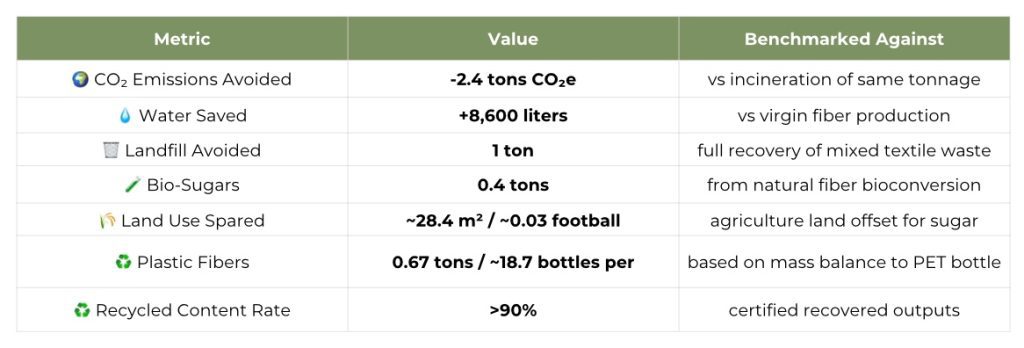

We track and quantify the full environmental impact of using materials produced through the BioFashionTech process, translating complex sustainability metrics into clear, actionable insights. For every ton of textile waste we process, we measure how much CO₂e is avoided compared to incineration, how many liters of water are saved relative to virgin fiber production, and how much waste is diverted from landfill. But we go deeper than that. Our system also accounts for the displacement of synthetic fibers. In doing so we are on track towards compliance with standards and regulations such as Extended Producer Responsibility (EPR), Corporate Social Responsibility(CSR), Global Reporting Initiative(GRI), and other reporting requirements.

BioFashionTech is proud to report a robust set of environmental Key Performance Indicators (KPIs), reflecting our continued commitment to sustainable innovation and circular economy principles. Our process avoids the release of approximately 2.4 tons of CO₂e per ton of material processed, compared to the incineration of the same tonnage. Furthermore, by diverting textiles from traditional production and disposal pathways, we achieve water savings of over 8,600 liters, benchmarked against the consumption levels of virgin fiber production.

Our impact extends beyond emissions and water. Each ton of recovered textile waste results in 1 ton of landfill avoidance with full recovery from a batch of mixed textile waste. For every tonne of textile waste the process can also generate 0.4 tons of bio-sugars, which are benchmarked against outputs from natural fiber bioconversion. Additionally, we spare approximately 28.4 square meters of agricultural land, equivalent to about 0.03 football fields, by offsetting land that would otherwise be used for sugar production. From a plastics perspective, our technology displaces 0.67 tons of plastic fibers, roughly equal to 18.7 PET bottles per ton processed, based on mass balance calculations. Importantly, our process consistently maintains a recycled content rate of over 90%, validated through certified recovered outputs. These metrics collectively underscore BioFashionTech’s leadership in developing high-impact, scalable solutions for textile waste valorization.

BioFashionTech also contributes towards global climate goals as laid down in the Paris Agreement and contributes towards six in the Sustainable Development Goals

Disclaimer : Given that BioFashionTech is still in the process of full commercial scaling, we currently do not have annual compliance reports or supply chain disclosures to share. In time, these will be displayed on this page.

All figures are based on our process LCA model (ISO 14040 aligned), updated June 2025